PROJECT

PROFILE

Wedge Roofing Demonstrates the Value in Refurbishing Commercial Roofs with Silicone Coating

Wedge Roofing proves that taking a closer look and considering different options for metal roofs can save on labor and costs for the customer

Photo credit: S-5!

BY David Feitl

PROJECT

PROFILE

Wedge Roofing Demonstrates the Value in Refurbishing Commercial Roof with Silicone Coating

Wedge Roofing proves that taking a closer look and considering different options for metal roofs can save on labor and costs for the customer.

Photo credit: S-5!

BY David Feitl

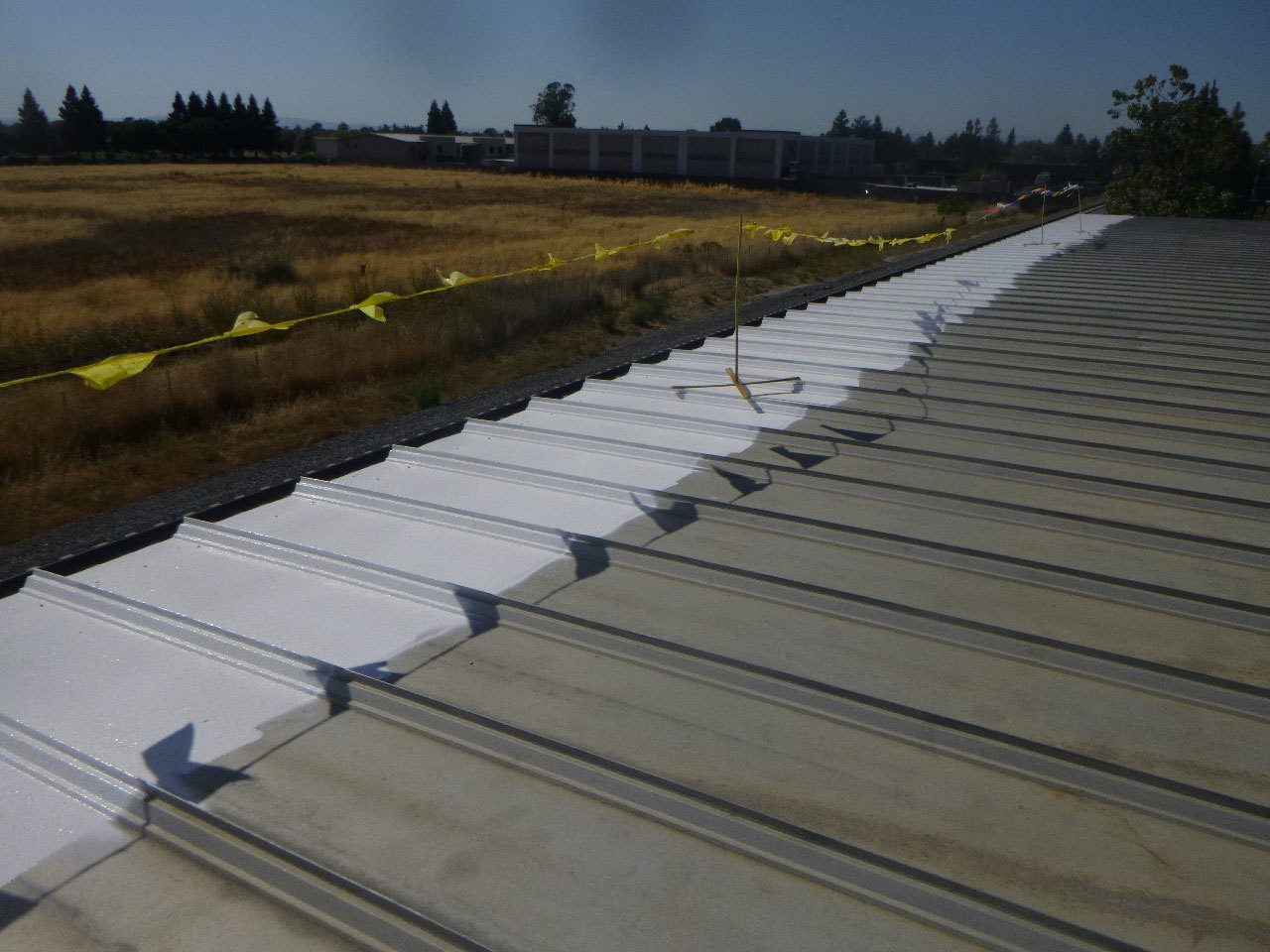

Earlier this year, multi award winner Wedge Roofing took home yet another Spray Polyurethane Foam Alliance (SPFA) National Industry Excellence Award when it won the Elastomeric Roof Coatings category at the 2022 awards ceremony held in San Antonio, Texas. The Bay Area contractor had yet again proven its salt, this time for completing an enhancement to a leaky roof atop a 1960s steel commercial building located in Santa Rosa, Calif.

Owners of the facility, which houses plumbing and heating supplies, met with numerous contractors to discuss and price a complete reroof. That endeavor would have included new metal, TPO over flute fillers, as well as spray polyurethane foam and an accompanying protective coating. The reroof had been recommended by those contractor groups in large part due to the 54-year age of the existing roof. But frankly, the quarter million price tag was beyond the owners’ allocated budget. Luckily, they ended up connecting with Wedge Roofing, who had a different solution.

Wedge inspected the existing 26,000-square-foot system and determined the panel laps, joints and fasteners, as well as a corroded 24-gauge galvanized steel box gutter were ground zero for the problematic leaks. With a diagnosis at hand, Wedge knew a complete reroof wasn’t necessary and that, instead, a fluid-applied restoration system would provide an effective fix. Wedge recommended the cost-effective solution to the facility owners, who happily agreed to move forward.

Wedge worked with material supplier Cal Roofing Supply to obtain the materials for the job, which was completed over the course of six days by installers Victor Ceja, Guillermo Martinez, Gaspar Penaloza, Juan Valle, Fortino Juarez, Edvin Lorenzo, and SPFA professionally certified project manager Gary Harvey.

The first step taken by the team was the repair of rusted and deficient areas in the existing metal roofing system, as well as priming to prevent any further corrosion or degradation. Next was the box gutter restoration, with Wedge Roofing’s team lining the integrated steel gutters with a 60-mil non-reinforced TPO integrated behind the interior parapet wall metal cladding.

“Our approach was to restore the roof rather than replace it,” says Harvey of the project. “Thus, we power-washed and cleaned the existing surface, then completed a series of component replacements and repairs.”

Wedge Roofing had to deal with wind from several acres of open field that threatened wind velocity and coating distribution.

New, oversized neoprene gasketed fasteners replaced existing fasteners. The installers also repaired and prepared all laps, joints, penetrations and seals.

Wedge and Cal Roofing Supply recommended Huntsman Building Solutions Thermo-Sil NP™ Silicone in the color white for the silicone coating. The high solids solution is a single-component, moisture curing silicone rubber roof coating system designed for use on existing smooth surface BUR, granulated cap sheet, well adhered acrylic coating, concrete, metal, spray foam and various single-ply membrane roofing.

“We were aiming to recondition and preserve the roof,” says Harvey. “The silicone forms a tough, durable membrane and protects the roof from damp, heat and UV. It’s a cost-effective way to extend the lifespan of the roof.”

Wedge Roofing applied 45 dry mils of the coating, then topped it with #11 Lucas granules in Fire White, embedded in the topcoat.

“This coating has been our go-to solution for more than a decade,” says Al Kennedy, president of Cal Roofing Supply. “In fact, there’s no appreciable weather degradation visible from our very first system installs.”

At the completion of the roofing process, traditional contemporary five-and-a-half-inch fascia gutters were installed to the upper roof pitched areas.

Harvey notes there were a few challenges with the job.

“Because of the significant water intrusion that would present during even the most minor of rain events, we were hyper-concerned about the power washing, cleaning and preparatory stage of this project,” he says. “To protect the valuable inventory inside the structure, we applied a protective covering overtop of it.”

Wedge and Cal Roofing Supply recommended Huntsman Building Solutions Thermo-Sil NP™ Silicone in the color white for the silicone coating.

Additionally, as is typical of a steel structure built in the 1960s, the inlaid sheet-metal Dutch gutter, which traversed over the main facility entrance, was opened and exposed to the interior while structural repairs and relining took place. Wedge successfully addressed this by placing temporary scaffolding over the door and window displays for protection during that phase of the job.

Another issue of concern? Wind from several acres of open field. Wind velocity and coating distribution to ancillary properties and equipment was a serious threat.

“Due to the configuration of the metal panel and slope of the roof, we were unable to use the normal rolling spray apparatus,” says Harvey. “Instead, four members of our team held multiple spray screens.”

Despite it all, Wedge Roofing completed the full job in less than one week, keeping any disturbances to the business’ operations to a minimum.

“At the end of the day, this job was a success on so many levels,” says Harvey. “As compared to the initial reroof recommendation, the facility owners saved vastly in costs for both materials and installation time. Additionally, in refurbishing rather than replacing, we were able to dramatically reduce this facility’s impacts on the environment, which is a win-win for all.”

David Feitl is vice president of global roofing and specialty products for Huntsman Building Solutions, a global leader in spray polyurethane foam and coatings systems. Contact David at dfeitl@huntsmanbuilds.com, visit www.huntsmanbuilds.com.