Video credit: Photos provided by Air Vent Inc.

SCROLL

DOWN

Supply Shortages Hinder Roofing Contractors During Hurricane Ida Recovery

Contractors Expect Supply Disruptions to Worsen Following Ida

By Chris Gray

Hargrove Roofing & Construction prepared as well as it could for Hurricane Ida, going so far as to have a 16-man crew sleeping on the ground in its Lafayette, La., office and creating makeshift shower stalls.

But the devastation caused by the Category 4 hurricane, compounded with the material shortages brought on by the global pandemic, are making storm recovery far more difficult than previous hurricanes.

“The storm will definitely make materials even harder to get, unfortunately,” said Billy Hargrove, CEO of Hargrove Roofing. “We have to get ahead and educate our clients on this so they understand.”

It’s a sentiment echoed by roofing contractors working in the areas slammed by Ida, and roofing professionals believe the material problems are only going to get worse from here.

Stress from Shortages

Ida is the sixth-costliest tropical cyclone on record, causing at least $50 billion in damages in the U.S. alone. Around $18 billion of that is in insured losses in Louisiana, surpassing Hurricane Ike from 2008.

“Damage was the worst we’ve seen in the five years of our company,” Hargrove said. “Entire roof systems being ripped off with insulation as a whole unit is something we haven’t come across before.”

On the commercial side, Nations Roof has endured multiple hurricanes over the years, and its national service center in Mobile, Ala., withstood the most recent storm. However, this is one of the first major hurricanes the company is taking on while dealing with the pandemic-induced material shortages and price increases.

John Geary, chief marketing officer for Nations Roof, said due to a loaded backlog his company has had materials to depend on, but even that is hitting its limits.

“Material availability, whether it’s membrane or insulation or adhesives or fasteners, are in such short supply that it’s very difficult to be able to get all the materials together to make emergency repairs on large areas of roof,” Geary said.

The silver lining, he said, is that Nations Roof has become creative in offering solutions to clients using other materials they may not have otherwise considered or expected.

Around $18 billion in insured losses occurred in Louisiana due to Ida, surpassing Hurricane Ike from 2008. Photos courtesy of Hargrove Roofing & Construction.

Trent Cotney, CEO of Cotney Attorneys & Consultants, said as more contractors begin substituting one product for another, they can expect more shortages to crop up. Even coatings, which were enjoying high levels of production and usage, are beginning to experience shortages.

Cotney told RC that Hurricane Ida will cause “significant stress” on the supply chain not just from the storm itself, but from refineries that provide the core ingredients for roofing products shutting down.

“We are in a crisis situation for sure, and these storms — and this is only the first of many — is going to exacerbate what we’re already facing,” he said.

To make matters worse, a shipping crisis caused a record-breaking 44 cargo ships to be stuck outside of California ports, which will only exacerbate supply chain issues further.

“This problem, I think, is worse than any of us had even imagined,” Cotney said. “A lot of manufacturers are predicting that this is going to cause some roofing contractors to go out of business — you just can’t get the materials to sustain your crews and do the work that needs to be done.”

Thankfully, companies are doing what they can to help. GCP Applied Technologies donated 460 rolls of roofing underlayment in 2020 and 2021 to emergency preparedness programs in Lake Charles, La., in preparation for a hurricane.

“Hurricane Ida has caused unprecedented devastation, forcing thousands of people out of their damaged homes,” said GCP Product Management Leader Brian Chang. “Unfortunately, Louisiana is hit hard by storms too often. That is why we began donating our GRACE ICE & WATER SHIELD® roofing underlayment to the Louisiana community last year.”

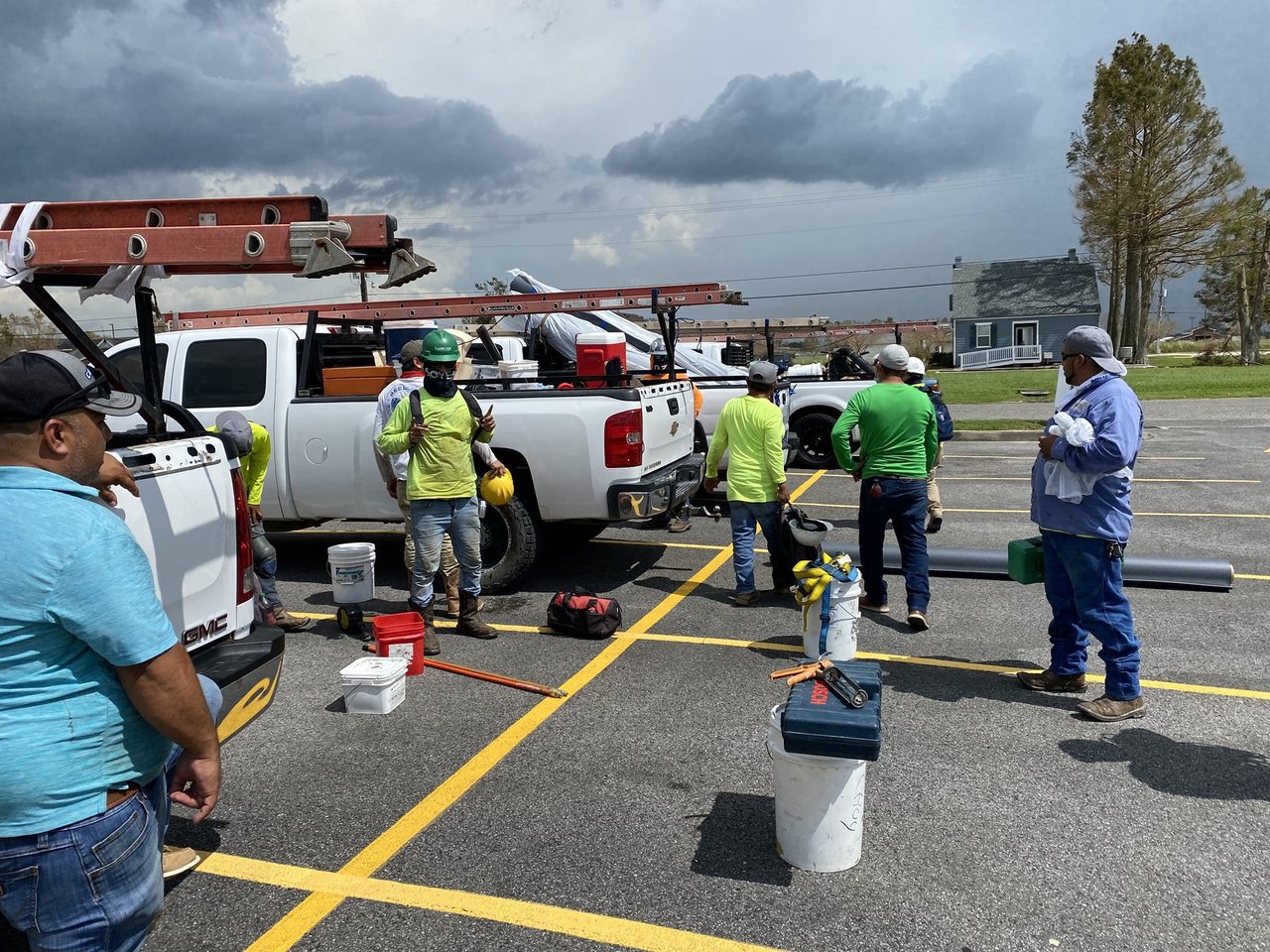

Crews with Hargrove Roofing prepare to work following Hurricane Ida.

Logistical Nightmares

Aside from supply issues, roofing contractors are struggling with logistical problems, whether it’s entering hazardous areas to make repairs or acquiring essentials like gasoline or food. Due to limited resources the problem is more pronounced than in previous years, said Michael Warren, director of operations at Roof Crafters in Hammond, La.

“I don’t think anywhere in the country is probably prepared for something like this where you have these mass power outages, resources being tapped, gas stations that are being emptied — there’s just nowhere to go,” he said. “The damage is bad, yes, but also traffic lights not being operable is a problem, so traffic is really bad. A commute that may take 30 minutes is now an hour and a half.”

Companies like Roof Crafters use local workers who are dealing with the aftermath just as much as their customers, meaning some employees simply can’t work due to downed trees or totaled vehicles. Warren anticipated Roof Crafters wouldn’t be operable until roughly 10 days after the storm made landfall.

Add rising lumber prices and material shortages to the mix and roofing contractors are left wondering how they’re going to help people in need.

“Every problem you could possibly face with this storm as a business, especially a roofing company that travels as much as we do — not out of state, but in our service area — it’s going to impact our business,” Warren said.

Chris Gray is managing editor of Roofing Contractor. Reach him at 248-244-6498 or grayc@bnpmedia.com.

SCROLL

DOWN