EPDM is now available in black and white non-reinforced membranes and a complete range of accessories is available to provide even more options for your roofing system specifications. The EPDM meets the requirements of ASTM D 4637, Type I, and is fully extruded, which produces fewer air voids, a more uniform thickness, and smoother sheets. JM’s EPDM combines two membrane layers to create a fully cross-linked monolithic membrane that can perform in extreme temperature climates and withstand differential movement. Its UV-stabilization properties offer outstanding ozone and weather resistance, delivering one of the longest service lives available. The white EPDM is backed by over 30 years of EPDM experience and installations, and meets or exceeds LEED and CRRC requirements for a reflective roof system.

For more information, visit jm.com.

SCROLL

DOWN

How can contractors help safeguard communities from future natural disasters? A promising option is the use of eco-friendly, fire-resistant materials, such as Hempcrete. Hempitecture’s Hempcrete is a 100% bio-based building material suitable for both residential and commercial insulation applications. It can be applied to walls, flooring, and roofing. Hempitecture announced that it is the first U.S. company to have its hemp lime formulation tested to ASTM E84, confirming it is 100% fire-resistant and a safe solution for buildings in high wildfire risk areas, as well as for homeowners and building owners seeking to enhance safety. The company stated that Hempcrete also helps reduce energy costs in completed projects by eliminating all thermal bridging in the envelope, thereby lowering the energy required to heat and cool interiors.

For more information, visit hempitecture.com.

The Garland Company Inc. announces the newest addition to its StressPly family of modified bitumen roofing membranes: StressPly Max. This patent-pending membrane is formulated for maximum strength, superior fire resistance, and exceptional weathering. The StressPly Max membrane features dual polyester and fiberglass reinforcement, delivering a high-tensile value further enhanced by a graphene-modified bitumen. The incorporation of graphene into the asphaltic compound provides strength with an internal reinforcement exceeding 1,000 pounds. Beyond its durability, graphene also enhances low-temperature flexibility, allowing the membrane to conform more easily to corners and complex roof details, while contributing to improved fire resistance. StressPly Max now also incorporates TripleBoost, Garland's additive blend designed to improve a roof's long-term performance.

For more information, visit garlandco.com.

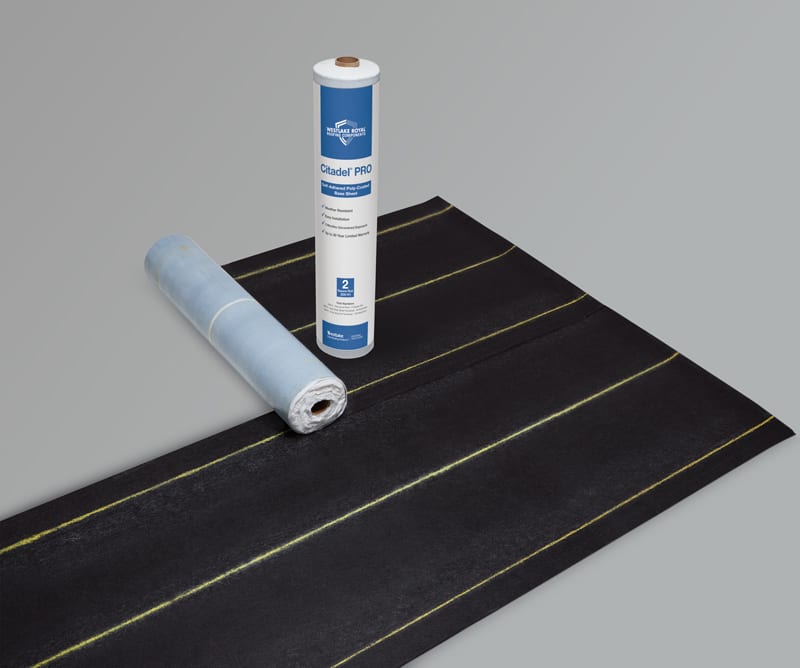

Westlake Royal Building Products, a Westlake company, has introduced Citadel PRO, a self-adhered poly-coated base sheet that provides protection and simplified installation for roofers when compared to mechanically fastened base sheets. Citadel PRO, which will be available in the Florida market, features a styrene-butadiene-styrene (SBS) modified asphalt core that self-seals around nail or screw penetrations to offer increased leakage protection. Citadel PRO is equipped with an easy-to-use peel-and-stick application to maximize deck adhesion and a poly-coated top surface for increased cap sheet adhesion. This eliminates the need for special tools or hot asphalt in the adhesion process while also providing superior moisture resistance and thermal stability. The poly-surface provides excellent foot traction and offers up to three months of UV resistance. Citadel PRO has been tested and certified to meet ASTM D1970 standards and Florida Building Code for both HVHZ and non-HVHZ regions as listed in FL14317; it is available in 3-foot by 66.7-foot rolls covering 200 square feet.

For more information, visit westlakeroyalroofing.com.

When roofing near a pool, contractors can protect their customer’s backyard from nails, debris and fine dust with The Catch-All’s newest product, the Pool Shield. Unlike tarps, the product is a breathable, durable 24-foot by 48-foot chute net that dries fast. When laid out over a pool, Pool Shield keeps it protected without messing with the pump system. It is made with the same high-strength, patented weave as The Catch-All's Job Site Protection, preventing water buildup and allowing debris to slide off cleanly instead of pooling up.

For more information, visit thecatchall.com.

Take on tough applications with DEWALT’s 20V MAX* metal cutting circular saw†. The 20V MAX* XR 7 ¼-inch Metal Cutting Circular Saw features a lightweight design and delivers up to 1,400 MWO of power to help maximize productivity on the job. This tool can complete a variety of applications with a 2 ⅝-inch depth of cut and features an integrated chip collector to help maintain a clean work area. The 20V MAX XR Metal Cutting Circular Saw (DCS383) will be available in spring 2025, either as a bare tool or as a kit.

* Maximum initial battery voltage (measured without a workload) is 20 and 60. The nominal voltage is 18 and 54, respectively.

†MWO using DCBP520 battery (sold separately).

For more information, visit dewalt.com.* Maximum initial battery voltage (measured without a workload) is 20 and 60. The nominal voltage is 18 and 54, respectively.

†MWO using DCBP520 battery (sold separately).

MFM Building Products introduces its new 48-inch Wind & Water Seal self-adhering roofing underlayment. The new product is composed of an embedded traction surface adhered to a high-temperature adhesive rated to 250 degrees Fahrenheit for use under metal roofing systems. Acting as an ice and water barrier, the 48-inch width eliminates the need to double layer along roof edges in some applications. Self-adhering and self-sealing around fasteners, the product is ideal for use along roof edges, eaves, valleys, and as a whole roof covering for secondary water protection. The product comes in a 48-inch by 50-foot roll size (200 square feet) and is packaged 30 cartons per pallet. Manufactured in the United States, Wind & Water Seal comes with a 10-year limited warranty.

For a free sample and information, visit mfmbp.com.

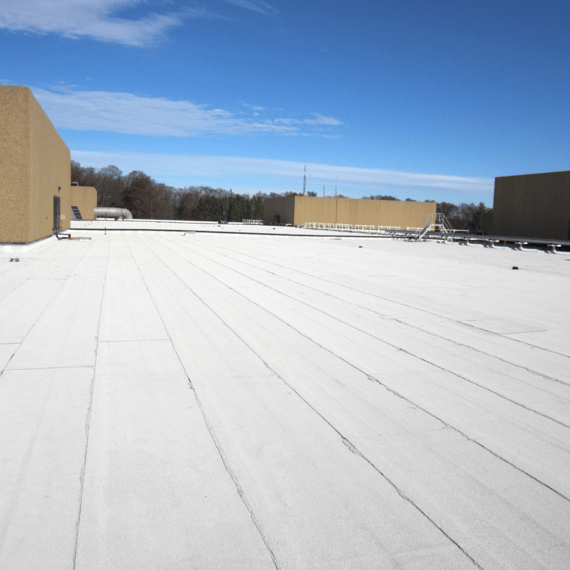

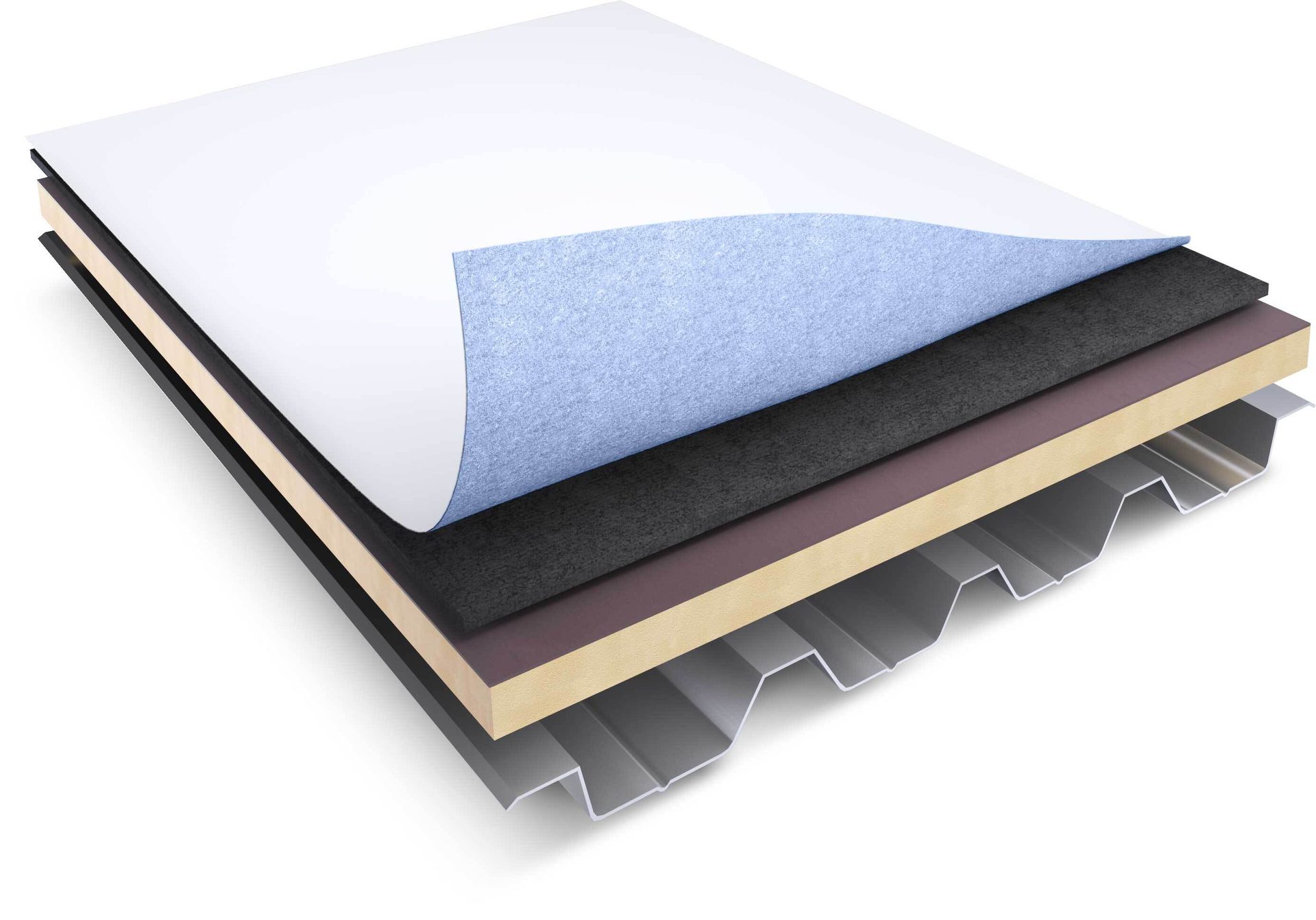

Duro-Last announced the expansion of its commercial roofing solutions with the launch of Duro-TECH and Duro-TECH Fleece TPO membrane product lines. Both Duro-TECH and Duro-TECH Fleece membranes feature Duro-Last’s exclusive anti-wicking, weft-inserted scrim with a density of 9 by 9 threads per inch — an industry-first for TPO membranes — eliminating the need for seam sealant during installation. This feature enhances installation efficiency, saving contractors time and reducing material costs while delivering watertight performance and durability. Additionally, each Duro-TECH membrane offers the most robust top film thickness in the industry — creating a resilient performance layer that stands up to the elements.

For more information, visit duro-last.com.