FOAMULAR NGX

Owens Corning

Owens Corning’s latest innovation in extruded polystyrene, FOAMULAR NGX insulation, contains a proprietary blowing agent that completely eliminates HFC 134a. It delivers a 90% reduction in blowing agent Global Warning Potentials (GWP) compared to legacy FOAMULAR insulation and is optimized to demonstrate a greater than 80% reduction in embodied carbon.

Created to meet anticipated demand after Canada and several U.S. states enacted stringent new environmental regulations to address concerns about high GWP and hydrofluorocarbon (HFC) blowing agents, this product demonstrates the fusion of smart material and resiliency. Officials say more than six years of research and development went into the intricate process of reducing blowing agent GWP without compromising performance.

Owens Corning took going "green" with this product the extra mile. A sustainability team used an environmental calculator to evaluate how switching from a competitive XPS product could reduce GWP. The potential is akin to taking 1,500 cars off the roadway, official said. It’s also manufactured with 100% wind electricity, is GREENGUARD Gold certified, reusable, and certified by Scientific Certification Systems to contain a minimum of 20% recycled polystyrene.

FOAMULAR NGX Details:

• Highly resistant to moisture and retains its high R-value even after prolonged exposure to moisture and freeze/thaw cycling

• Sustainability Profile validated by a third-party verified Environmental Product Declaration and Optimization Report

• A greater than 80% reduction in GWP qualifies as 1.5 products towards LEED 4.1 points or Options 1 and 2 under the Materials and Resources: Environmental Product Declaration

• FOAMULAR NGX is Underwriters Laboratory (UL) Listed and Factory Mutual (FM) approved, and is available in all states and Canada

Seal-Fast® Liqui-Flash

Mule-Hide Products Co.

Sealing complex and non-traditional spaces on the rooftop takes a particular combination of versatility and strength that Mule-Hide Product’s Seal-Fast Liqui-Flash provides. As such, the sealant is an exceptionally versatile maintenance and repair solution. The one-component, 100% solids, non-shrink, polyurethane sealant can be used in typical and difficult-to-access applications, including flashings, skylights, and pitch pockets.

It's also compatible with a wide range of substrates, including metal, polyurethane foam, aged smooth asphalt, aged modified bitumen, aged PVC and aged EPDM. Use on TPO systems requires Mule-Hide Si TPO Primer. The new Seal-Fast is also compatible with Mule-Hide Products' acrylic and silicone roof coatings, making it an ideal choice for polyurethane foam roofs damaged by hail.

Seal-Fast® Liqui-Flash Details:

• Single-step application process using a brush or a ribbon nozzle

• Can be used on TPO roofing systems when primed with Mule-Hide Si TPO Primer

• Seal-Fast Liqui-Flash is available in three colors – black, white and gray

• Packaged in 10-ounce caulk tubes, 20-ounce sausage tubes, 1-gallon pails, and 3.5-gallon pails

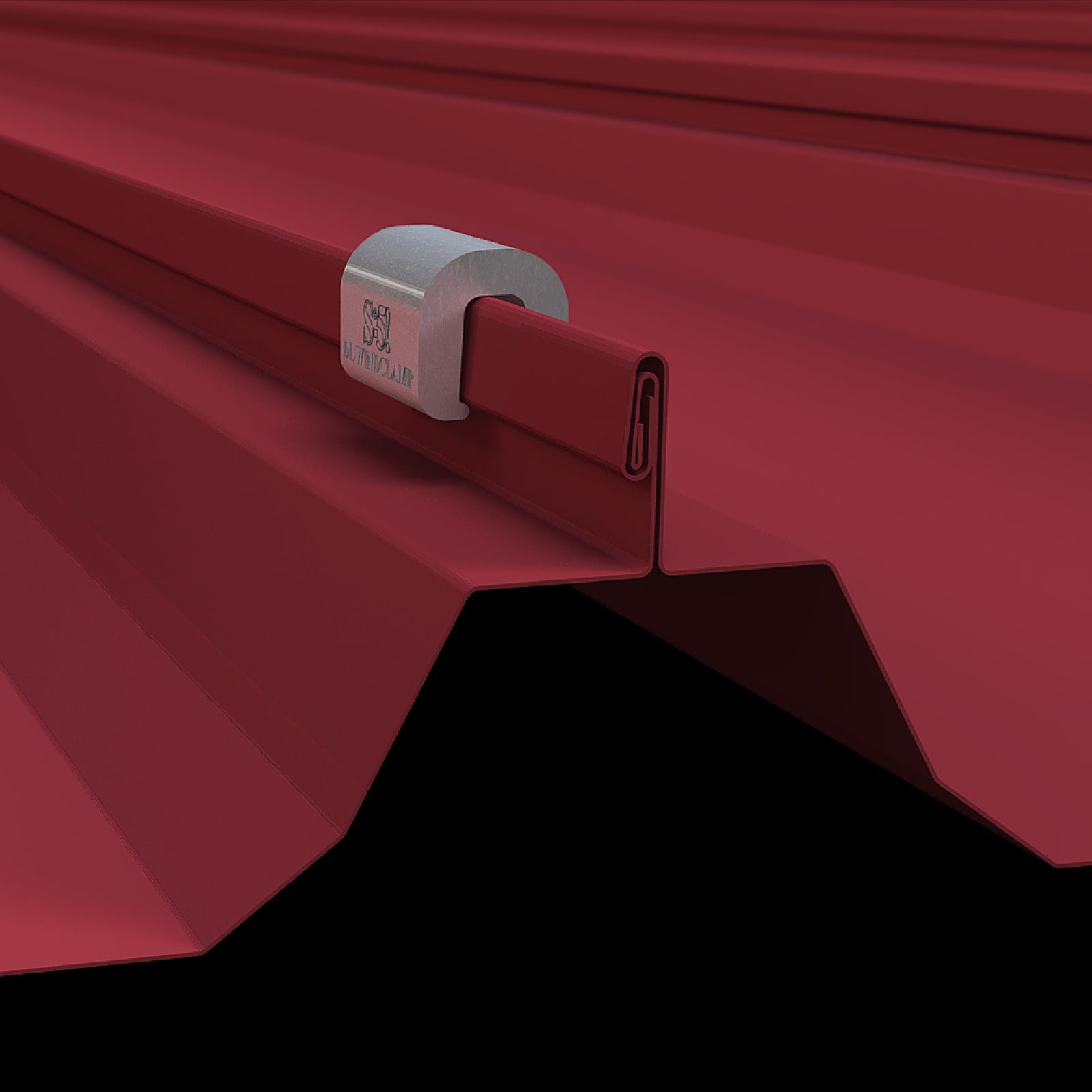

WIND CLAMP 2X

S-5!

Metal roofing’s increased popularity in both commercial and residential settings has sparked a new wave of innovation on the manufacturing and installation fronts. The latest edition from S-5! is designed to increase wind resistance for metal roofs, particularly in the wake of the record hurricane and storm season we just experienced in 2020.

Now the third of S-5!’s WindClamp series, the new WindClamp 2X is designed for specific double-folded standing seams. The small aluminum clamps are placed over the seam to prevent separation from the roof’s mounting clip. The clamp-to-seam technology has been described as highly cost-effective, and a solution to preserve rooftops in some high-risk roof zones.

“The magic is not in a generic ‘seam clamp,’ or in a seam clamp that ‘fits okay’ or ‘fits’ multiple seam profiles,” said S-5! CEO Rob Haddock. “The magic is in knowing how to design a seam clamp for this purpose and for a specific panel profile. S-5! WindClamps can increase strength by 100, 200 or even 300% with test protocols to prove it.”

WIND CLAMP2X Details:

• Prevents multiple failures – including seam separation and clip disengagement

• Cost-compelling alternative for new construction

• Can also be used in retrofit applications for compliance

• Will meet current codes and wind standards