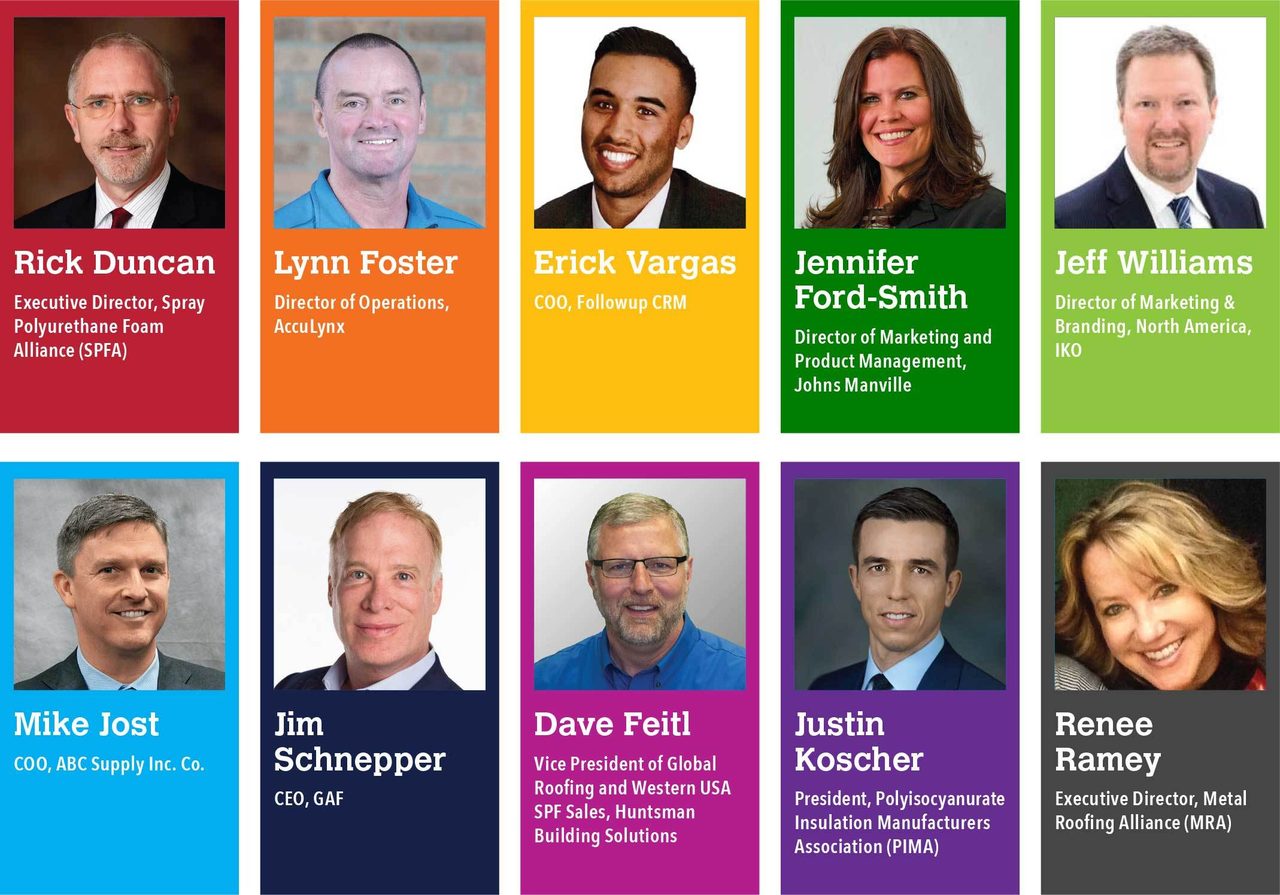

State of the Industry Q&A

From the distribution warehouses around the country, to the manufacturing facilities that churn out the roofing products that contractors consider their lifeblood during peak season, the challenges of the past year have been daunting.

Trying to gauge the pulse of the roofing industry each and every year continues to be a challenge, particularly as roofers undergo monumental changes in how they price, sell, manage and organize their jobs. In addition to the survey circulated last fall that laid the foundation for the 2022 State of the Industry Report, RC also sought out the opinions of leaders from all segments of the industry.

As part of RC’s continuing coverage, here’s what several leaders had to say about their experiences in 2021, where and how they found some stability, and where they believe the industry is going as a whole.

RC: How would you assess the state of the roofing industry in 2022?

Dave Feitl (DF): The industry proved very resilient considering the varied, unprecedented issues 2021 delivered. These included raw materials supply challenges and product delayed at the ports, topped off with the COVID-19 pandemic and how we’ve had to navigate through that as well. I feel our contractors have done a tremendous job at keeping their companies afloat and remaining optimistic considering it all. There was and still is so much work available and not being able to supply enough products to our contractors over the past year has been frustrating from the manufacturer’s side, but we’ve worked through as well as possible.

Jennifer Ford-Smith (JFS): 2021 probably had to be the most challenging year for not only Johns Mansville, but the entire industry that will be remembered in history. Veterans with 35-plus years history in the industry reported never seeing so many challenges occur all at the same time. You know what they say, what doesn’t kill you makes you better, and while significant challenges arose with the supply crisis, it forced us to rethink our business; find creative solutions to significant challenges; and it, hopefully, positioned us to be a better supplier to the market in the future.

Rick Duncan (RD): Unlike new construction, where spray foam insulation is installed and often serves the entire life of the building, existing buildings will need roof retrofits, which spray foam supports. For this reason, the spray foam roofing market has been relatively stable. As an industry, we probably have not grown the market share of spray foam roofing as much as we could have, but demand has remained consistent and we don’t foresee any major shifts in that during 2022.

Mike Jost (MJ): After 2020, we were excited to start getting back to “normal.” While the year was not without challenges, in many ways 2021 exceeded expectations. ABC Supply continued expanding across the country, opening eight new locations and acquiring three companies. We strove to help our customers navigate material shortages and price volatility and provided them with useful tools like myABCsupply. Our associates came together to support deserving national causes like Homes For Our Troops, the Make-A-Wish Foundation and many worthy causes within the communities our branches serve. All in all, we’re very proud of our strong sales performance and all we’ve accomplished this year.

We expect that supply chain challenges will continue into 2022. While that won’t make keeping up with increased demand any easier, we’re optimistic about helping contractors be successful. We’ve learned a lot navigating the challenges so far. We offer tools and resources that can help contractors manage their projects and customers throughout a busy season, and our large national footprint allows us to leverage our size in solving problems for our customers.

Lynn Foster (LF): When you zoom out and look at 2021 from an industry perspective, there’s a couple different things we saw. First, it was a slower year in terms of storms meaning a lot of insurance restoration roofers were having to be more aggressive and agile in terms of their sales process, or they had to shift their focus more to retail sales. From what I’ve read online, it seems like we’re likely to see an increase in storms in 2022, similar to how the 2020 season was.

We also saw a continued reliance on technology. I think this is something that’s here to stay through 2022 and beyond. With coronavirus, homeowners have gotten used to a certain way of doing business — digital signatures, credit card payments and financing, text reminders — are all things that customers have come to expect as a baseline for doing business.

Finally, I think that as we head into our third year of the pandemic, roofers — and people in general — are pushing for “normal.” We’ve seen this in the roofing industry with the resurgence of in-person events and companies returning to the office. As we move into 2022, I think we’ll continue to aim to return to a pre-pandemic life.

Renee Ramey (RR): Residential metal roofing is still going strong! We have seen little slowing during what would normally be the “slow season” (winter) as pent-up demand continues to remain high. Members of the MRA that we’ve spoken to are busier than ever, with backlogs carrying them well into 2022.

Justin Koscher (JK): The roofing industry is well-positioned to play an important role in the growing conversation around the need to retrofit our existing building stock to lower energy use and cut carbon emissions. Additionally, we see an increasing number of local and state jurisdictions adopting policies like building performance standards that require owners to act affirmatively over a period of time, typically over multiple five-year compliance periods, to lower energy use in their buildings. (PIMA’s recent) report produced by ICF International demonstrates how roof replacements can make significant contributions to lowering whole building energy use. We should be doing all we can to educate building owners on the opportunity presented by reroofing.

Erick Vargas (EV): In 2021, every business was challenged by the pandemic in different ways. Followup CRM moved from in-person to full remote workforce. Thankfully, being in the software business, our sector has boomed. With most of the world needing to work remote, people now realize the importance of CRM software and tracking information in the cloud. The pandemic accelerated the roofing industry’s need for software by several years and Followup CRM is looking to meet that demand.

Jeff Williams (JW): Agility was one of IKO’s core values long before the onset of the pandemic. This principle guided us through challenging times during these past few years and helped enable us to consistently serve our North American customers with local support, backed by a global roofing network with 70 years of experience.

We have, at times, suffered from inefficiencies and work stoppages just like everyone else. Additional PPE requirements and distancing mandates can create a challenging manufacturing environment. We sense a lot of industry uncertainty when talking to our ROOFPRO contractors, but as we enter year three of COVID disruptions, we know that we have a proven formula for tackling challenges together.

Jim Schnepper (JS): Our industry has its share of challenges right now — supply chain issues, material shortages, rising costs and an ongoing labor shortage are top-of-mind for all of us. However, for every challenge there is ultimately a solution — and in this case I believe that technology, innovation, strong partnerships and maintaining our focus on how we can best serve our customers and their customers will help us continue to move forward as an industry. My team has heard me ask many times, “What can go wrong?” We game out situations so we are not reactive but rather proactive with a play book.

RC: How did the supply shortages of 2021 impact business and where did you find stability?

RD: Early on in 2021, contractors had contracts in place which were based on lower material costs. But when the material shortages started and led to an increase in the price of those materials, many contractors were forced to absorb those price increases. So that was a challenge to their bottom line early on. But now the shortages have been going on for a year and newer contracts include provisions that allow contractors to pass along materials price increases to their customers.

RR: Supply issues plagued the residential roofing market across the board — regardless of roofing type. Many MRA members did experience some delay in material supply but, from what we’re being told, the supply issues were short-term.

The biggest shortage impacting the metal roofing market remains the lack of installers. The MRA has been participating in an industry-wide effort to capture the interest and attention of laborers, encouraging them to consider a career in the metal roofing industry. The MRA also has participated in the development of training materials specific to metal roofing that are being developed by the NRCA. This program, once completed, will provide a great resource for individuals seeking installation training of various metal roofing styles.

LF: As a company, AccuLynx wasn’t impacted by the global supply chain crisis in the same way our customers have been. Instead, we fielded a lot of questions and concerns from our customer base and focused on supporting them with key integrations that allowed them to have the most up-to-date product lists.

So, for us, a big thing was our direct integrations with ABC Supply and SRS Distribution. We’re able to show our customers real-time pricing and availability at each of these retailers so that they can create accurate estimates. These integrations also allow our customers to directly place orders through AccuLynx, eliminating the need to manually pick up the phone and place an order with their local branch.

MJ: ABC was affected by the supply chain crisis just as almost everybody was in 2021. It was difficult to predict lead times on many of the materials we supply, and some were difficult to purchase at all. Therefore, it was more important than ever that we worked with key suppliers and kept our lines of communication open. That’s where we found stability — with our vendor and customer partners. We were, and still are, all in this together. As long as we recognize that and keep talking about options every day, we’ll continue to fight through the challenges.

EV: This shortage affected our product roadmap because clients needed a better way to track which opportunities would be profitable for them and which were going to be delayed due to materials not being available. During this time we were able to design features so that our clients could pull the reports that they needed and continued to close opportunities that they were able to complete.

JFS: By March of 2021, we had suppliers of ours putting us on allocation. So even if our plants had line time and labor, there wasn’t enough raw materials to push through the process. Beyond the allocation, came transportation issues, so even if a supplier could get us product, they struggled to find rail and/or trucks to transport it in our facilities. Call outs were an issue due to COVID’s mass spread, and navigating the ever-changing landscape of managing a workforce during a pandemic had its challenges as well. I think the positive outcome was that it brought us even closer to our customers. The key was communication and transparency, which can only be done through the long-standing relationships that JM has been able to establish with our customer base.

RC: What do you think was learned and how will that impact the industry moving forward?

MJ: We know that our manufacturers did the best they could in very difficult circumstances. Do we wish they could have filled every purchase order on time? Of course we do. But we know that they feel the same about their raw material suppliers. Some have told us that they will be increasing their safety stock, some are broadening their supply chain, others are adding capacity. Overall, our suppliers had efficient processes that were disrupted by the pandemic and ensuing supply chain crises, and we expect to see their efficiencies return in the future. Exactly when that will be, we wish we knew.

LF: I think one of the biggest things we’ve learned over the past two years is that we can conduct business remotely even in the contracting world — and that’s something we never thought was possible back in 2019. And while face-to-face interactions are ideal, not every customer interaction needs to be. We’ve actually even found that roofers can create more time and drive efficiency by taking some of these interactions digital.

Roofing contractors don’t need to drive all the way across town to collect a payment, they don’t need to be on a job site to know what’s happening with their crews, and they don’t need to be climbing on roofs to take measurements. Instead, roofing software like AccuLynx can help provide these insights and data points.

EV: One of the biggest lessons learned is that a hybrid workplace model is the future. Especially with the millennial generation, working from home needs to be a strategic consideration when building a company in this day and age.

DF: From our vantage point we learned a lot of lessons. Typically, we like to keep a 30-day inventory on hand but we have beefed that up. Additionally, from an R&D standpoint, we have looked at newer technologies we hope to introduce in the future. These solutions are designed to help us avert issues surrounding any raw materials shortages that may occur. We also increased our storage capacity and enhanced our ability to manufacture product at both our Arlington, Texas and Boisbriand, Quebec facility locations. This effort will help facilitate production in multiple locations, as well as to avert and overcome any future issues and disruptions either manmade or caused by natural disasters.

JW: It’s really been a question the last couple of years of how to problem solve on the fly, and using things like remote learning tools to resolve issues and share knowledge in real time. Many things that were only done face to face we’ve now established can still be accomplished from across a closed border. It’s going to make us better and more responsive in the long run, even when there are technical challenges. It’s also a great tribute to the outstanding people who work for us and the flexibility that they’ve demonstrated in what has often been really less than ideal circumstances.

JS: One of the most important factors in our ability to keep producing the product that kept homes, families and businesses safe and dry during the pandemic — not to mention the hospitals and healthcare facilities that provided critical care during this historic crisis — was our designation as an essential business. That designation meant that our plants could keep producing, while we worked to ensure a safe workplace for our employees. Once we were designated as an essential business our focus was on how to operate safely and keep our employees from contracting and transmitting the virus. I promised our employees that we would make all our facilities safer than going into their grocery store. We lived up to that promise.

JFS: As we did with our contracting partners, transparency and constant communication is necessary with our suppliers during supply situations like this.

We did everything we could do to help contractors continue projects they had started. We worked closely with them to look for viable alternates, even sometimes accepting competitive components to keep the project going. We also worked with our building owner customers to educate them on viable alternates.

RC: How did you help support contractors as their needs changed throughout the pandemic?

LF: For us, 2021 was really a continuation of 2020. We continued to face many of the challenges of 2020 throughout this year as our lives continued to be dominated by the coronavirus pandemic. And for AccuLynx, that meant that we continued to find ways to support roofing contractors while they worked remotely, or in a limited contact capacity.

With that, we saw a large amount of adoption in AccuLynx features that support remote work. We also saw roofers looking for new ways to sell. Unemployment rates were still high at the start of 2021, meaning that money was tight for many homeowners. Features like AccuFi take an expensive reroofing project and allow roofing contractors to offer homeowners financing options that fit into their monthly budget. Similarly, we saw many contractors take advantage of AccuPay or online payment processing tools that allow homeowners to pay by credit card, debit card, and e-check.

EV: The most tangible way Followup CRM helped contractors during this pandemic was helping them with a hybrid workplace model. Many of our contractors had to go fully remote or partly remote, which brought new challenges to organizing the back office. Sharing about best practices from some of our top clients as well as increased support for our clients really helped them get through this past year.

DF: We worked more closely with our contractors during 2021 than we ever have in the past. With the shortages that occurred, filling orders was inevitably more challenging. We had to closely advise our contractors on planning ahead, on our stock levels and alternate products they could use so they would have product when they needed it. As a manufacturer, we also experienced a few disappointing moments in 2021 when we really thought we’d be getting the raw materials needed to manufacture our roofing and envelope products and, like so many others, we were unable to get them. It was a tough year in many ways, but we feel we did our best working with our contractors to keep them as informed and as supplied as possible.

JW: IKO is doubling down on digital training opportunities. During 2021, IKO filmed and produced 19 educational videos, which will serve as a reboot of our popular Blueprint for Roofing series. Each episode focuses on a different aspect of roof installation. Training videos have traditionally been our most popular content on YouTube.

JS: In many ways, the pandemic was a catalyst that accelerated our work in a number of important areas — including digital solutions and remote education. Today, we’re doing more online training than ever before, and contractors are using our digital technology to continue to sell without having to meet in person with customers. I am excited to continue this path to reach deeper into our contractor universe more efficiently to provide new levels of service, innovation and creativity.

RC: Have you seen any progress in the workforce shortage in roofing, and what encourages/discourages you about the current approach?

JFS: The NRCA is putting in a tremendous effort to elevate the perception of the industry with programs like ProCertification and others. The (Roofing) Alliance’s partnership with colleges and universities is also supporting that effort. I feel we still have a long way to go — all trades do.

JS: The labor shortage affects much more than roofers — it’s a nationwide problem for employers of all industries. However, I believe the key is attracting more young people to the roofing trade. Our GAF Roofing Academy program is an important step in this area, which offers tuition-free, hands-on training and access to career opportunities for young people — 80% of whom come from underserved communities.

MJ: Some of our customers are still struggling with the workforce shortage. We have seen contractors become more open to trying new products, tools and services that save them time and manpower, and therefore help alleviate their workforce challenges. It’s encouraging to see contractors getting creative to find solutions when simply hiring more people isn’t an option, and we’re always trying to make their jobs easier too. For example, we offer tools like myABCsupply and integrations with software like GAF QuickMeasure, EagleView and AccuLynx that can help contractors do more with less effort.

RD: The SPFA, like the NRCA and other key industry groups, believes the industry greatly benefits when it provides expanded workforce training initiatives that improve the skills of up-and-comers and address future worker demand. Immigration reform is another area of concern and is tied to the shortage of workers. We support reform that specifically addresses worker demand, increases border security, expands E-Verify (to combat illegal immigration), and supports visa reform that allows workers to enter the U.S. legally when our economy needs them.

RC: What are you optimistic about in 2022?

RD: There are a number of things going on in federal legislation to increase building energy efficiency. There’s going to be a demand for higher performing insulation for buildings and improved air tightness. Spray foam, including when used in roofing applications, helps solve these problems. Spray foam has a great opportunity with commercial buildings, which are inherently less efficient. There is an opportunity for improved roofing systems. We also see there may be some growth in the area of roofing systems that are more durable and resistant to wind uplift, hail damage, hurricanes and storms as we have seen severe weather and weather-related events increase in both frequency and intensity.

RR: The demand for quality metal roofing is high and expected to continue growing. That means now is the perfect time to get involved. The shortage of installers is hindering growth in many areas as there are simply not enough contractors to cover homeowner demand. In addition, the profit margins for metal roofing are on average higher than with most other roofing options. Couple that with increased weather events due to climate change, the desire for more sustainable roofing options and the better long-term value that metal roofing offers, and you’ve got a hot market with no end in sight. The metal roofing industry offers several training opportunities for those new to the market as well.

MJ: The last two years have taught the industry the importance of being prepared and flexible. We’ve experienced a pandemic and the supply chain challenges that it spurred, and it seems that weather is becoming less predictable and more extreme each year. We’ve also learned that technology is critical in our industry. We’re optimistic that the industry has learned from these challenges and will only be stronger as we move into 2022 and beyond.

LF: Looking ahead, I can say that I continue to worry about material and labor shortages. We’ve seen how these things affected our customers and the industry as a whole, and I am concerned that this will remain a trend in 2022. We’ve continued to see suppliers sending out notifications of price hikes. On the more positive side of things, I think we’ve learned to navigate living with coronavirus. So, moving into 2022, I’m looking forward to returning to an environment that more closely resembles normal. We’ve already seen in-person industry events pop back up. We just had IRE in August and we’re headed to New Orleans for the 2022 event. That definitely gives me hope.

EV: Followup CRM was designed to help drive sales in 2022. Tracking leads pipeline and developing new opportunities with business development allows our clients to take care of their clients and continue to serve them at the highest capacity. Followup CRM allows our clients to automatically follow up with their leads and bids, saving them time and winning them more jobs.

DF: We have spoken with many contractors and they all seem highly optimistic. The book of contractor business seems to be very full. There is an existing backlog of business caused by the pandemic’s initial shutdowns and slowdowns alongside new demand. All those projects need to be completed. If we can get the supply situation under control going into 2022, it is anticipated contractors will have a profitable first and second quarter. Everyone is anticipating a busy year ahead.

JW: The roofing industry is made up of hard workers who demand the most from themselves and expect the same from the materials that they use. IKO is optimistic that our customer base will continue to insist on best-in-class products, partnering with us to raise the bar (or raise the roof).

RC: What are you proudest of as the industry tries to recover from the challenges of the past year or two?

JK: I am proud to count myself as part of the roofing industry and am deeply appreciative of the men and women who have continued to manufacture and install roofs across the U.S. and Canada despite all of the challenges, both on a human level and an industry level. One of the bright spots of the last two years has been the public’s growing appreciation for the manufacturing sector and skilled trades. I hope our industry can take this opportunity to grow even stronger. Based on what I have seen from the polyiso industry the past two years, we are certainly up to the challenge.

RR: The MRA has done a stellar job generating new, relevant, and engaging materials aimed at educating homeowners about quality metal roofing. These materials cover topics that are often overlooked or brushed over quickly but have real meaning to homeowners. That includes offering details about the roofing process, specifications covering metal roofing options, and more in-depth education on what to look for or ask when replacing your roof.

The MRA also has found great success in sharing testimonials and examples of reroof projects, giving homeowners inspiration and incentive to move ahead with the metal roofing projects. Driving consumer awareness through our various outlets is key and MRA realized the highest engagement results thus far, showing that the MRA is reaching the correct audience with pertinent, meaningful, and accurate information in a timely manner.

LF: For me, I’m really proud of the fact that AccuLynx has created a phenomenal suite of products that allows contractors to grow and operate their businesses in a changing world. When I first joined AccuLynx nine years ago, I never would have thought that we’d become so reliant on technology in the face of a global pandemic. We’ve created these easy-to-use tools that can help any roofing business get organized and find efficiencies, leading to an increase in their own sales.

JS: I cannot overstate how proud I am of what our phenomenal workforce accomplished, despite the crisis unfolding around us. So much extraordinary work was done in 2021, and our teams not only helped us survive, but thrive during this time. It is also important to note that all of this was achieved while maintaining a relentless focus on safety, which is no small feat. I’m very proud of how our teams came together to keep each other safe, even as we worked to keep our promises to our customers.

JFS: Johns Manville is over 160 years old. We have been through many ups and downs throughout our history, and what has always got us through is our people. 2021 was one of the most challenging times for the industries we serve, and it was our people coming together, being laser focused on the challenge at hand, working with customers, and putting in the hours are what makes us proud to be a part of the JM family. We are also proud that we were there for the industry as a whole — JM participated in every tradeshow, in person and having leadership available to answer the tough questions.